Live PTO

Modern boats, not just fishing craft and workboats but also pleasure craft, increasingly demand auxiliary power for driving on-board machinery such as winches, pumps or compressors. The traditional method of meeting these requirements has been to take an auxiliary drive from the front of the main propulsion engine, which involves expensive and space consuming vee-belt installations.

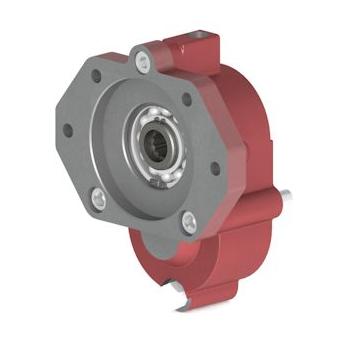

PRM marine transmissions now offer you compact, low cost and efficient alternatives: a choice of clutched (on PRM1000) or direct drive (on PRM500 and PRM750) power take-off units which bolt directly to the rear face of the gearbox, either as factory fitted options or as assemblies for retro-fitting to existing gearbox installations. Both versions are specifically designed to drive hydraulic pumps, whether of the gear, vane or piston type; they are not intended to be adapted for driving an outrigger pulley since the mounting

Direct Drive Power Take-Off

Available on the PRM500 and PRM 750 the direct drive power take-off is driven directly from the gearbox input shaft; consequently it will operate at all times when the engine is running, and since there is no clutch for disengagement of the hydraulic pump, provision must be made in the auxiliary hydraulics circuits for pressure by-pass to the reservoir when power to the pump is not required. A pair of 1:1 ratio gears, providing sufficient offset between the gearbox output shaft and the centreline of the power take-off to ensure there is sufficient clearance between the hydraulic pump and propeller shaft coupling.

Capacity

All power take-offs are specifically designed for driving hydraulic pumps to SAE J744C series 'B' specification with splined input shaft and either two-bolt or four-bolt fixing. The maximum power which can be transmitted is 22 KW (29.5 bhp) per 1000 rev/min engine speed; this equates to a torque of 209 Nm (155 Ibf.ft. - 21.33 kgm.).For PRM1000 the clutched power take-off gives pump rotation the same as the engine, where as the direct drive power take-off for the PRM500 and PRM750 will give opposite rotation. Power to the pump is not affected by the normal use of the gearbox for propulsion duties. All ancillary power circuits driven by PRM power take-offs should be designed in accordance with the recommendations of the hydraulic equipment manufacturer, and should be properly safeguarded against overloading.

PRM power take-off units fit on the rear face of the main gearcase and are driven by the input shaft; consequently they can be operated at all times whilst the engine is running, The power take-off replaces the end cover which is normally fitted and performs the functions of the end cover by sealing the gearbox against loss of oil and correctly positions the input shaft rear bearing. Power take-off units also provide the link between the gearbox and the hydraulic pump.

.jpg)